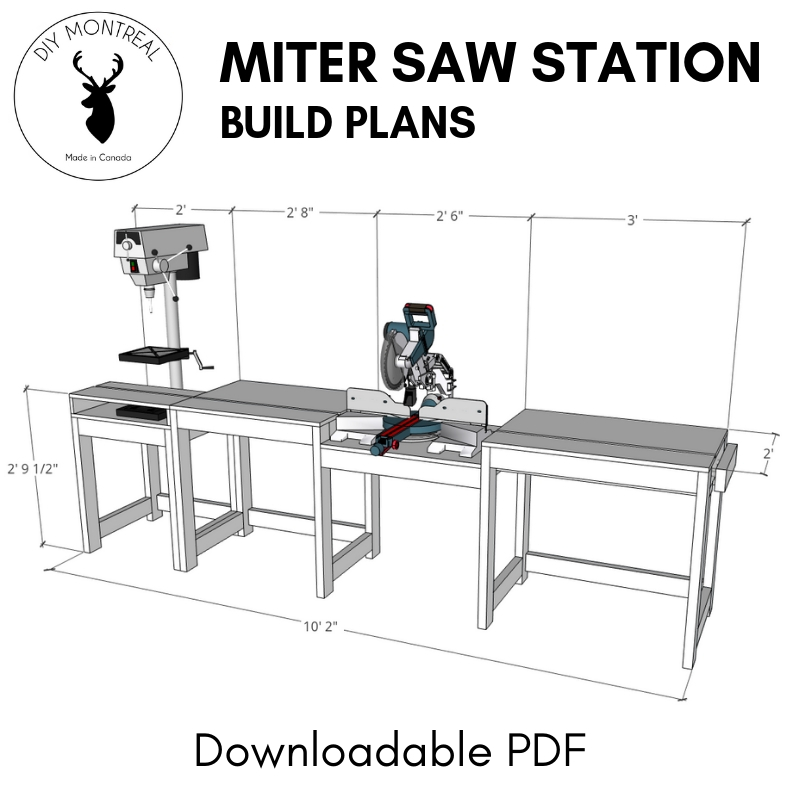

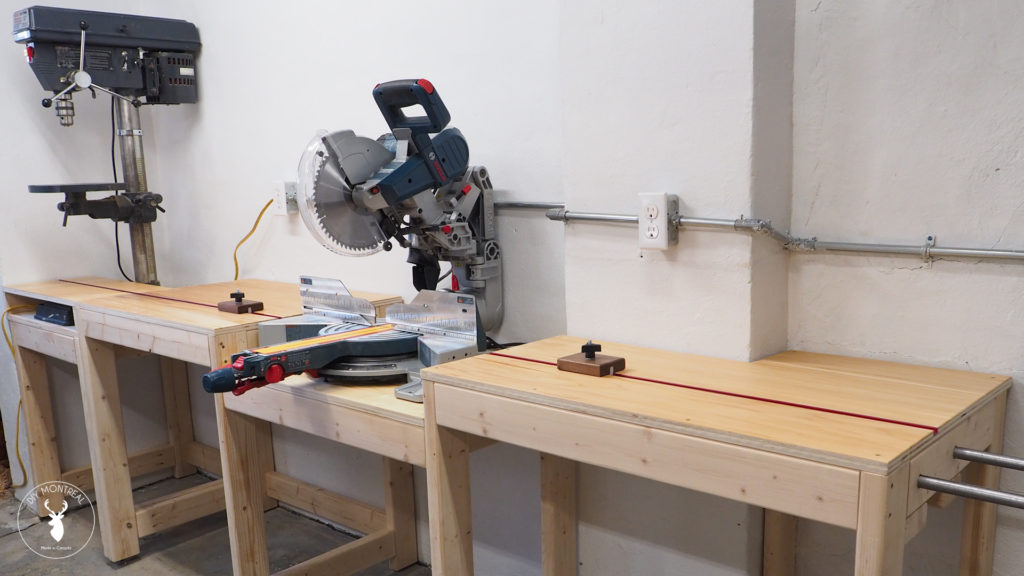

Having a dedicated miter saw station not only makes your workshop more functional, but also makes using your miter saw safer and more convenient.

There are many miter station build plans out there, so what’s different about this one? When designing this workstation, my goal was to integrate the following:

- Space saving extension wing

- Integrated drill press

- T-track integrated stop blocks

- Leveling feet

- Simple, cost effective build

Here are the tools and materials used for this build:

– GET THE PLANS –

Miter Saw Station Build

The base will be built entirely with 2 by 4s so I set up a temporary work zone so I could use my miter saw to cut down all my lumber as per the build plans.

Next was time for pocket holes. I basically made 2 pocket holes at the end of each board that would serve as a horizontal stretcher. I could then turn to working on the assembly.

Using pocket screws, I built up the first frame in a box formation that would make up my first module. You’ll notice that I left the bottom front side open, and this was intentional to allow flexibility down the line to decide how I want to use the space underneath the workbench later on.

Saying that my floor are uneven would be an understatement. I have a huge slope and nothing is level. So to make things easier I used a trick I picked up from Jay Bates and decided to use carriage bolts as leveling feet. After drilling a hole, I just tapped in a T-nut and threaded in the bolt. I repeated this on all the legs so I could level out the entire build.

I then moved onto building the next module. This one will habor my drill press, so I’m making it a little shorter, but otherwise the assembly process was essentially the same.

After adjusting the leveling feet, I moved onto the third module. Now this one is a bit different, not only because I had to modify it to work around this column, but mostly because it will include an expansion wing to support long boards. After flipping the legs upside down, I added 2 support stretchers from underneath, trying to keep everything square with the help of a level and a speed square. Just a side note – the build plans do not take into account this column. Oh, and I also wanted to point out that you can just as well use regular screws and butt joints if you’re not a fan of pocket screws.

In hindsight, I should have thought of making these holes before assembly, but in any case, the idea is to use a Forstner bit to drill all the way through the right side stretcher. After a little sanding, I did a test fit to make sure the steel pipe would fit.

Using the same Forstner bit, I drilled 2 holes using a depth stop set to 1 inch deep. Then over at the module, I did a dry fit to make sure the holes were correctly aligned. I made similar holes into another block, again not going all the way through, then did a dry fit with that piece as well. With everything sliding freely, I mixed up some 5-minute epoxy which I applied to both surfaces and pushed the steel pipe all the way in. After letting it dry, I applied some paste wax to the steel pipes to reduce friction and help the pipes slide smoothly.

Before screwing down the plywood top, I first clamped down the top to test the extension wing and make sure it could slide smoothly. If you’re getting too much friction, you can sand down the 2 by 4 just a little and test it again. Once I was satisfied with that, I could secure the plywood top with some screws after first making some pilot holes.

I went on to screw down the tops to all the other modules, but first added a center support piece to the module on which the drill press will sit.

With all the tops on, it’s important to ensure that the modules all level before adding the middle platform that will harbor the miter saw. I tweaked the carriage bolts until it got it just perfect.

I then built a simple platform using more 2 by 4s and pocket screws, and screwed down the plywood top.

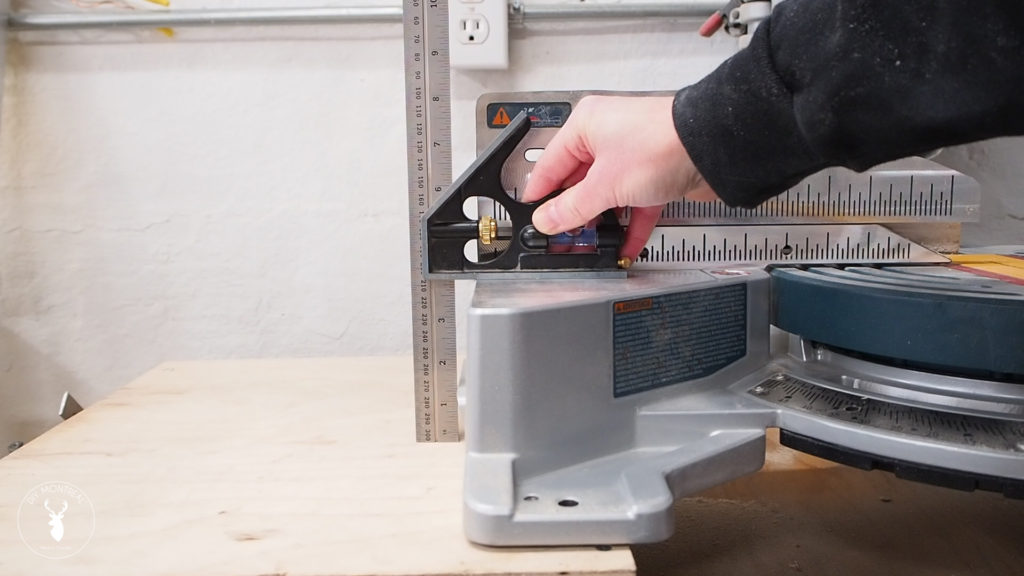

Next, I used my combination square to precisely measure the height of my miter saw’s base, and so I could then easily carry that measurement over to the modules, and mark all 4 inner legs.

I used some clamps to help line up the platform with the markings and then secured it with some screws from underneath. I also secured the other modules with a few screws through the legs.

I’m going to add an upper level to the drill press module so the top sits flush with the top of the workbench. So after cutting down a few pieces to size, I secured the top to the support legs. Note that this shelf will simply sit in place so it can easily be removed if needed. But because I’m going to add a T-track, I want to make sure the shelf is locked into place and won’t move, so I simply attached a couple stops blocks to secure it in place.

I’m going to add T-tracks to the workbench with stop blocks using my router and a ¾ straight bit, setting the bit height at about half the thickness of the track for the first pass. I set up a guide that I clamped to the workbench to make sure I was nice and straight, and after the first pass I adjusted the bit so it was just above the thickness of the track since I want the T-track to sit just below the surface of the workbench.

After that I cut my track to length using my miter saw and did a dry fit before gluing down the tracks. I’m using Weldbond glue for this since it adheres to different surfaces like metal and wood. You could also just screw down the track, but I like to use glue.

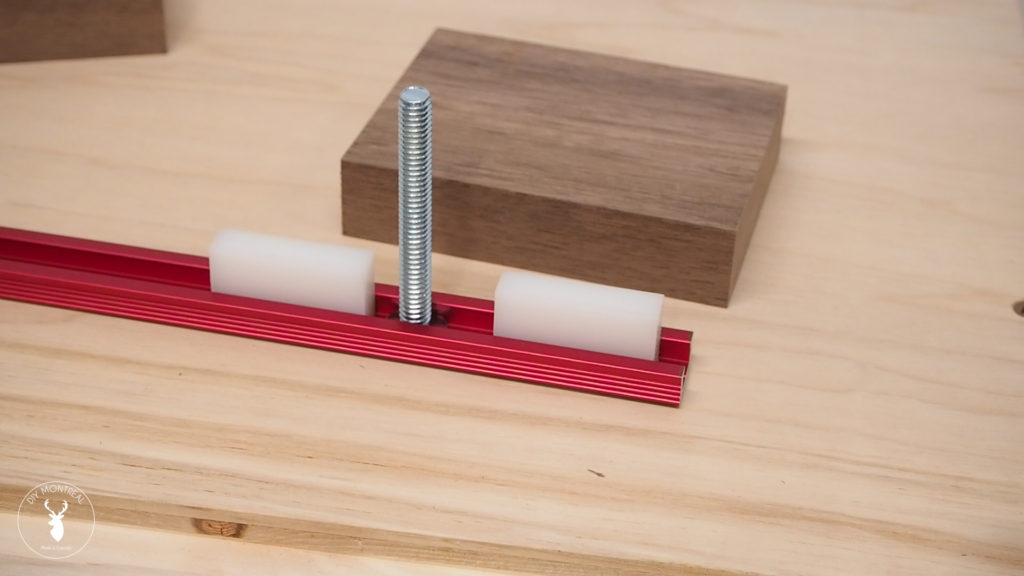

With the T-tracks in place, I could move onto to making the stop blocks. I’m making these out of small blocks of walnut, but any hardwood will do. For the runners in the track, I’m using UHMW runners but you can use hardwood for this as well. I like to use these plastic runners because they’re a perfect fit and and won’t be affected by changes in the weather or humidity. So the idea is something like this, with the runners and a T-bolts in the track and then a block on top.

But first I need to cut a small dado that will fit the runners. You can do this in different ways, but I find the table saw to be the easiest. After chamfering all the edges, I used some super glue to secure the runners to the stop block, and then made a hole for the bolt through the center.

To finish it all off, I applied 2 coats of shellac to the stop blocks and the workbench top, making sure to avoid getting any in the tracks.

If you’re interested in getting the plans for this build CLICK HERE. The plans include 3D assembly diagrams, cut lists and cutting diagrams, materials list and much much more.

Before signing off, I wanted to point out that I will eventually be finishing off the bottom half of the build in a future video. I’m not sure if I’ll make drawers, shelves, doors, or probably a combination of all 3 storage options. As for dust collection, for now I’ll simply be hooking up my shop vac, but I’ll likely address a more permanent solution in a future video as well.