Today I’m going to show you how to make a lazy Susan. It’s basically the same as making two round cutting boards and installing Lazy Susan turntable hardware. I’ll also show you how I made a homemade circle cutting jig to cut the circles with a router.

For this project I used three types of hardwood: cherry, walnut and maple. I made a 16 inch circle for the top and a 9 inch circle for the bottom.

Here are some of the tools and materials you’ll need:

- Turntable hardware

- Cutting board oil

- Food safe glue

- Compass

- Upspiral bit

- Roundover bit

- Bench cookies

SUBSCRIBE TO MY YOUTUBE CHANNEL

How to make a wooden Lazy Susan

Since I’m working with raw lumber, I started by cutting off the end before cutting a few pieces to rough length, slightly longer than the final dimensions. I then ran the pieces on jointer several times until the bottom face was flat.

I could then flip that face up against the fence to joint the edge.

After that, I ran the boards a few times through my planer until the top face was nice and flat.

Note that the boards don’t all need to be the same thickness at this point.

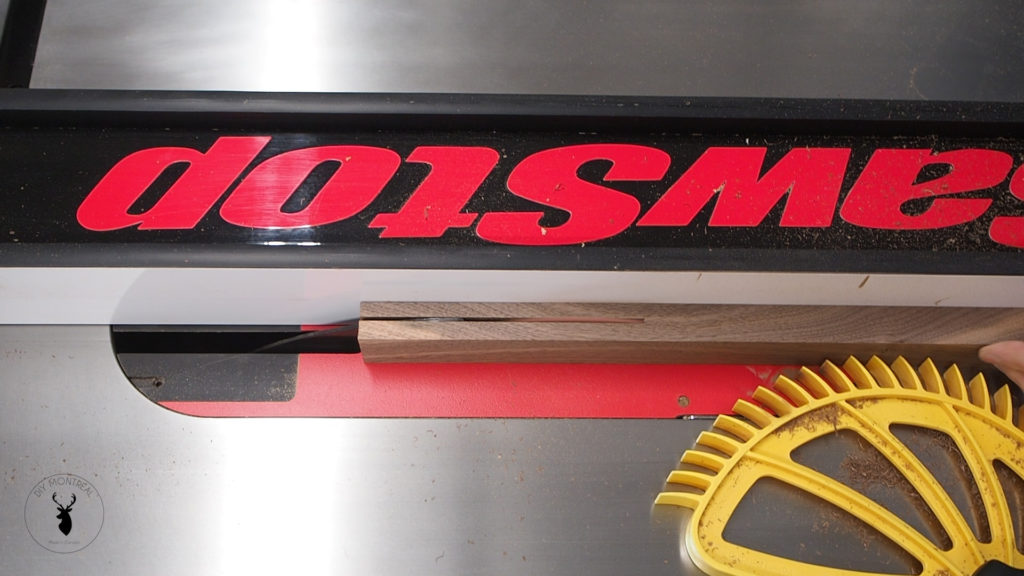

Next I set my table saw to rip the boards just wider than I want the final thickness of my cutting board to be.

Since the blanks will be flipped 90 degrees before glue up, this way they’ll all be the same thickness.

I also wanted a few thinner strips of walnut so I ripped down some of my blanks into thinner strips.

After deciding on a pattern it’s time for glue up. Since this board will be about 18 inches wide and my planer is only 12 inches, I’m going to do this glue up in 2 parts that I’ll assemble afterwards. Given that this lazy Susan is intended for food like cheeses and charcuterie, I made sure to use a food safe glue like Titebond II that is both food safe and water resistant.

After letting both parts dry overnight, I could then run them through my planer a few times on each side of the board, one after the other, so that both the top and bottom sides were flattened and both boards planed down to equal thickness.

I’m now ready to assemble both parts, but I noticed that the joint wasn’t perfectly straight so I did a quick pass on the jointer to flatten the inside edges. I can now assemble both parts simply using some glue. It’s important to get this joint flush so take your time here. It helps to use small clamps along the joint to help get both surfaces perfectly lined up.

I almost forgot but you’ll also need a second smaller board for the bottom part of the lazy susan. For this I simply planed 2 boards on face and glued them up.

To cut out the circles, I’m going to use my router with a homemade circle cutting jig. To make the jig I first need to remove the bottom plate from my router.

I flipped the plate over onto a piece of thin plywood and marked out the 4 screw holes and roughly marked the center hole.

I drilled out the center hole using a large Forstner bit. Then using a smaller Forstner bit I countersunk the 4 screw holes using the depth stop on my drill press. I could then drill all the way through those holes using a bit slightly larger that the size of my router’s screws.

After screwing the plywood onto the router and installing an upspiral bit, I traced out a center line onto the board. You can then make a pilot hole for the desired size of the circle’s radius. I made my hole at 8 inches since I wanted a 16 inch wide circle.

Next I found the center of my board and made a very small pilot hole. To use the jig I simply put a small nail through both holes and tapped it in with a hammer.

I first took a shallow pass going clockwise and progressively lowered my bit after each full revolution. You’ll also want to vacuum up the saw dust regularly to make it easier on your router. Ideally you should use a plunge router for this, but since I don’t have one, I manually plunged the bit each time I lowered the bit and it worked out just fine. Eventually I made it all the way through and was left with a nice round circle. This was probably the most satisfying part of the project for me.

I repeated the exact same process for the bottom circle, simply adjusting the size of the radius to make it smaller.

Okay so I now have both parts of my lazy Susan that I’m going to assemble with this turntable hardware. But before that I have a little more prep work to do like rounding over all the edges with a roundover bit and of course, a little sanding. I started at 80-grit and progressively made my way up to 220-grit.

Since the board will be washed I’m going to water pop the board and let it dry in order to raise the grain before sanding it once again with 220-grit.

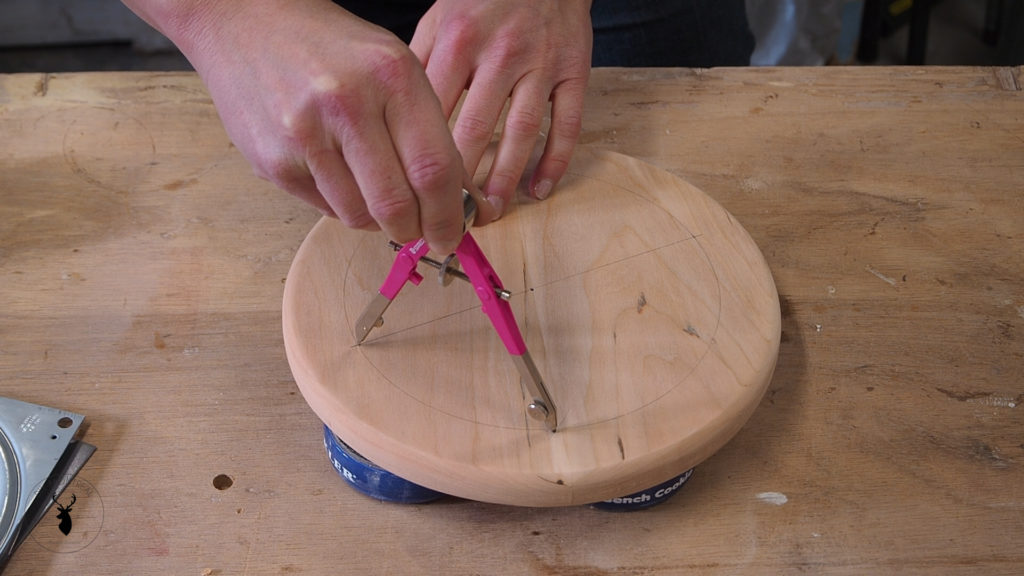

There are different ways to mount the hardware and I’ll try to explain the one I used (it’ll make more sense if you watch the video!). My biggest concern was to get the hardware perfectly centered. I started by measuring the distance between the holes and setting my compass to exactly half that length, then drew a circle using the center hole left behind by the circle jig. Next I drew a line through the circle. It doesn’t matter where you draw it, as long as it passes through the center point. I adjusted my compass to make the opening wider, then drew 2 arcs using the intersects as pivot points. I then drew another line through the circle using the spot where the arcs intersect and the center point as guidelines. Both lines should now intersect at 90 degrees and should line up with the holes in the hardware.

I used a small bit to make pilots holes all the way through so the holes would be transferred to the opposite side. It was at this point that I realized my mistake. I should be using the tiny little holes for the bottom plate. Luckily this was an easy fix. I measured the distance between those holes, and adjusted my compass to make the new markings. After drilling the new pilot holes, I flipped the board over and countersunk the holes using a small Forstner bit and the depth stop on my drill press. The holes should be big enough for the screws that come with the hardware.

I then repeated the whole process to mark the holes for the top board and drilled some shallow pilot holes, this time making sure not to drill all the way through.

Before attaching the hardware I gave it one final sanding then vacuumed and wiped away all of the sawdust. I finished the board with food grade mineral oil, applying a generous coat and letting it sit for 20 minutes. I repeated this process 4 times and then finished by wiping off all the excess oil.

I lined up the hardware with the pre-drilled holes, starting with the top and screwed it down.

I could then position the bottom piece and screw it down from above.

Now all that’s left is to enjoy and spin your Lazy Susan to your heart’s desire.